“Vishnu Priya Chemicals has now gained a pivotal position in chemical Industries. Since the year 1994, we have been manufacturing fine chemicals, specialty chemicals, and pharmaceutical items to meet the needs of clients from various industrial units”

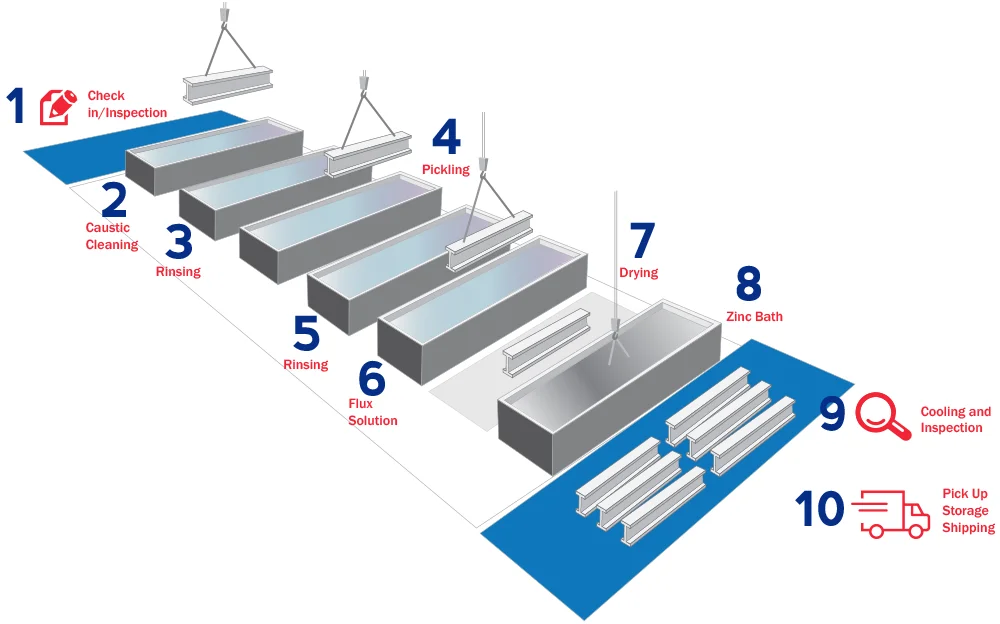

Galvanizing is the practice of coating clean, oxide-free iron or steel with a thin layer of zinc or zinc alloy to protect the surface against corrosion.

High activity fluxes

Facilitate high quality galvanizing. These fluxes should be considered especially when base metal surfaces can be given only a minimum amount of surface preparation or are difficult to prepare for galvanizing.

Medium activity fluxes

Will allow high quality galvanizing where the base metal has been given adequate surface preparation.

Low activity fluxes

Will make good quality galvanizing possible after painstaking base metal surface preparation . These are also used for blanket flux on the kettle/bath.

FOUR FUNDAMENTAL STEPS OF GALVANIZATION

The preparation step consists of cleaning and pickling operations that free the surface of dirt, grease, rust and scale

The fluxing step serves to dissolve any oxide that may have formed on the iron or steel surface after pickling and prevents further rust from forming. This cleaning can be accomplished with either a preflux solution, a top flux on the kettle, or both.

Clean, oxide-free work is galvanized by immersion into molten zinc.

Finishing operations include removing excess zinc as well as quenching and passivating post-treatments.